From farms around the world to a neighborhood near you, quality sod matters in more ways than meets the eye. While quality rolls made with Magnum machines look great and feel even better, the benefits of big rolls go beyond aesthetics. Professional sod installation ensures that form meets function everywhere you’ll find our mark of excellence.

To share all the intricacies that make the installation process so important, we’re taking a look at where you can find our installer rolling out in the future. Before we dive into the details, let’s go over the best practices for quality sod installation.

Timing and Weather Conditions

Timing is everything when it comes to rolling out healthy turf. Professional installers ideally look for cool and rainy seasons to minimize stress and ensure root health. They also avoid installation during droughts or extreme heat, because these conditions can risk dehydration and root system failure. Making sure that the soil is adequately moist but not overly saturated supports optimal root growth and blending of the sod into existing soil.

Installation on Slopes

For many installations, slope and grading are crucial considerations. When installing sod on a slope, the strips need to be perpendicular to the slope to help the sod take root. To prevent the sod from slipping, installers will stagger the joints between strips and secure the edges. The A-Series installer helps ensure a seamless finish on any surface thanks to the precise controls and optional roller attachment.

Trimming and Handling

In many applications, installers will need to carve the sod with a sharp knife to contour it for the desired shape around edges, curbs, beds, and sprinkler heads. Rolling out the sod carefully will help avoid damage to the roots while making good contact with the soil. Our installer avoids compaction or damage throughout this process with flotation tires that evenly distribute the weight of the machine.

Additional Considerations

To ensure your sod takes root, soil preparation is essential for any successful sod installation. Your soil should be well-drained, fertile, and free of debris and rocks. With the grading attachment, our A-Series installer can clear the way. We’ve even seen some professional installers use it to spread fertilizer and topdress the soil!

In every step of the installation process, our installer is the versatile superstar that makes efficient, professional outcomes possible. Now that you’ve got the best practices down, let’s dive into the intricate aspects of sod installation for residential and commercial spaces!

Residential Sod Installation

With new neighborhoods popping up every day, developers can’t wait for seeds to grow if they want to start filling up their property! That’s where sod comes in. With big rolls made possible from farmers who use Magnum’s line of harvesters, discerning developers can get the right grass for any neighborhood. Here’s a look at how Magnum helps to build a thriving greenscape faster.

Step 1. Preparation

As discussed earlier, prep is key to ensuring a healthy, lasting lawn. To prep the soil for sod installation, the pros take several steps. First, they will remove all existing vegetation and debris. Next, they condition the top layer of the soil by tilling and compacting as needed. To even out the slope and grade for drainage, installers may use the grader bar attachment on our A-Series installer to create an even surface.

Step 2. Rolling Out

When laying sod, installers will start at one point and steadily unroll the sod in long strips. Our installer helps with this process with precise throttle controls and hydraulic arms that maintain proper tension. In each pass, installation crews lay the strips side-by-side while ensuring the edges are tightly together. In some cases, crew members will pull seams together with a sod rake. They also trim the sod to fit areas on the property. Once the crew finishes rolling every strip of sod, they attach the drum roller to the A-Series installer to evenly press the sod into the soil and ensure complete contact.

Step 3. Watering

Immediately after installing sod, crews need to start watering it thoroughly. Adequate moisture will keep the soil consistently moist, but not overly saturated. Regular watering is needed for the following few weeks. As installers continuously water and fertilize different areas, they should also check for seams and bunching up of sod. These are easy problems to remedy with the Magnum installer’s roller, but if left unchecked, it may be difficult for the turf to properly root in the new environment.

Step 4. Finishing

For a flawless finish, crews may opt to fertilize the newly installed sod. In addition to fertilizer, they may also water the soil to promote complete absorption. Fertilizer and proper watering encourages strong root development and healthy growth. These finishing touches help the grass recover from the stress of the installation process.

Throughout every stage of the residential sod installation process, the A-Series installer is a valuable asset that helps the entire process go smoothly. With multiple attachments available, this is one investment that pays dividends to installation crews all over the US. But you won’t just find our machine at work on the jobsite!

Major League Sod Installation

In sports arenas and golf courses across the country, you’ll find our equipment rubbing shoulders with groundskeeping royalty. When installers need the best turf fast, there’s only one name they trust to help them make it happen. Here’s a look at how Magnum has helped shape some of the nation’s most recognized fields!

Essential Elements for Stadiums

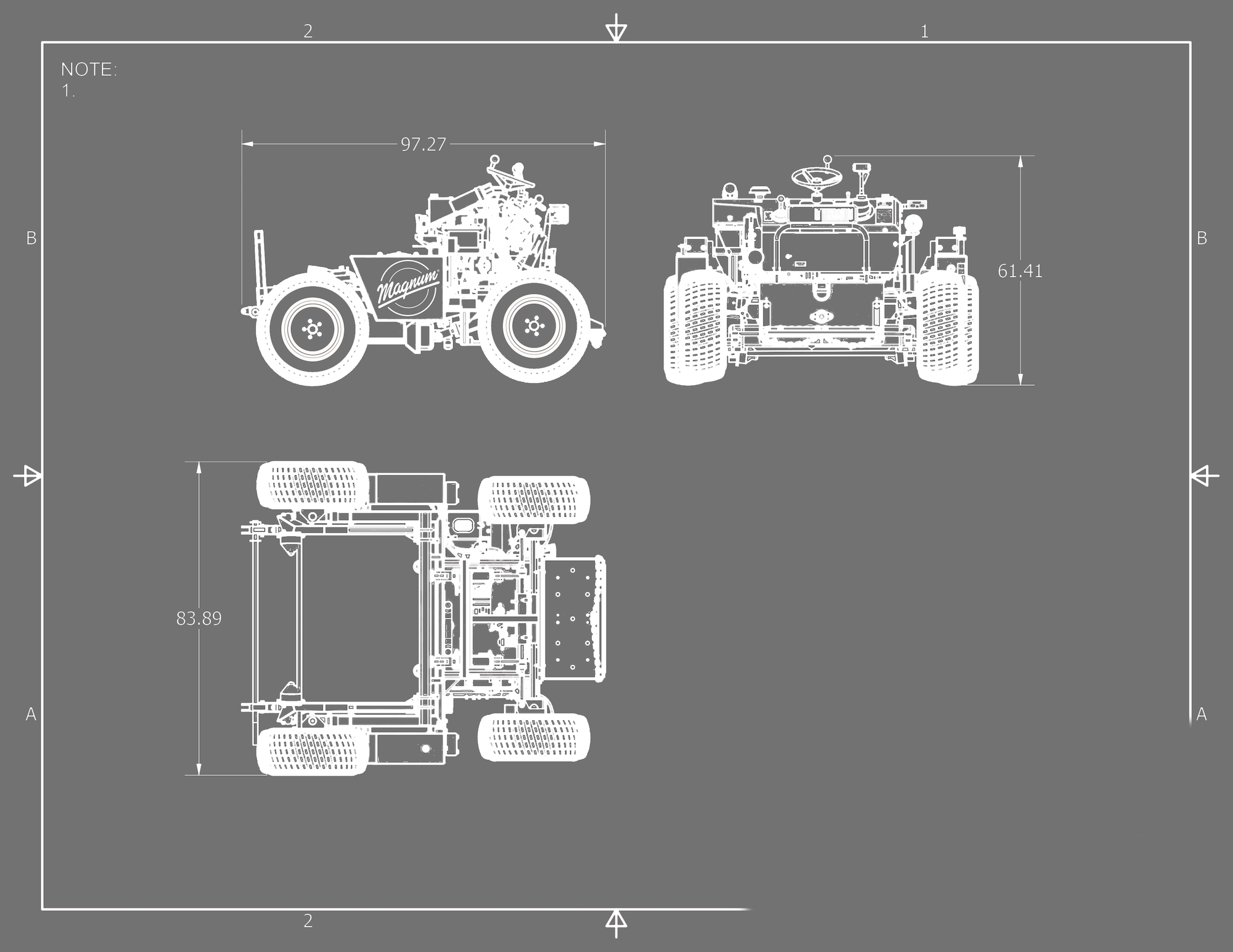

There’s a lot that goes into making a field of dreams dreamy. That’s why our machine is designed with every crucial detail in mind. From the tight turning radius and lightweight design, to fast operation and precise controls, the A-Series installer is the multi-talented MVP installation crews need for the following reasons.

Efficient Installs

Groundskeeping crews operate under extremely tight turnaround times for field installation and maintenance. With work needing to be completed before the start of a new season or after a major event, there’s no time to waste! To install large rolls quickly, many teams rely on our installer’s speed and versatility to efficiently get the job done.

Exceptional Durability

To ensure the field stays beautiful play after play, installers need a crew member that’s just as reliable. Our installer answers the call with flotation tires that can be adjusted to minimize the machine’s impact on the sod and soil. Less stress on the sod during installation ensures a durable surface throughout every second on the clock.

Effortless Maintenance

Maintaining a pristine playing surface is not only essential for aesthetics but also for player safety! To make replacements easy, grounds crews keep an installer around for quick turnaround times and a professional finish every season.

An additional consideration for field maintenance is proper field drainage and adequate padding below the surface. The A-Series installer helps maintain the underpinnings with the grader bar. This attachment provides an even surface below the sod which keeps drainage protected while building up essential padding throughout the field.

Step 1. Preparation

To refresh a field for a new season, the process starts by removing the last season’s sod and preparing the soil. In this stage, our installer helps crews roll up old strips of sod and load them on a truck for composting.

Step 2. Sod Delivery and Staging

As the new sod is delivered to the stadium, the hydraulic clamps make gentle handling effortless—even though big rolls can weigh over 1000 pounds! With inspection complete and the floor prepped for installation, the operator can easily pick up the first roll to begin installation.

Step 3. Installation

Throughout the installation process, our machine ensures precise tension and placement with the push of a finger. As the machine nears the opposite end of a stadium, crew members cut the sod to finish the placement. In close quarters, the machine’s tight turning radius makes quick turnarounds effortless to keep the process running smoothly. When installation is complete, the machine can be easily loaded on a truck with a forklift and hauled away.

Magnum Knows Your Sod

We know what it takes to provide the world with the best sod because we’ve been doing it for decades. From an easy operator experience to a pristine finish, the A-Series installer continues to be the pro’s choice for all the right reasons. Sod installation is a snap with our expertly engineered machine and the service and support that makes Magnum ENP a household name in the industry.

To get pricing for a new installer, use our online tool or talk to our team!