There are so many things about the turf grass industry that you have to experience to fully understand why we love it so much. Magnum’s team enjoys a comfortable office just like anyone else. But it took decades of blood, sweat, and tears from our founders, technicians, and farmers to get where we are today! You could say, innovation for turf grass farming is a family tradition around here.

Dive into our in-depth read to learn about our history and future!

Table of Contents

Early Days in the Field

The Original BR Harvester

Designing the Ideal Equipment

Netting a Loyal Following

Next-Gen Turf Grass Farming

From Our Family Farm to Yours

Early Days in the Field

Our family spent the earliest days in the turf grass production industry waking up early and going to bed late, working alongside the best agricultural minds in Kansas. Gary Dover spent his first years in this industry sowing seeds and harvesting by pulling slabs and small rolls from his land with lots of labor hours. Before big rolls, as we know them today, ever existed, he had an idea that would change the industry forever.

The Original BR Harvester is Born

His hard work paid off in more ways than just a successful sod farm. Gary’s vision for a more efficient farm became a reality in his first roller prototype. This early innovation widened the cut and compensated for the extra weight by rolling the harvested sod on a conveyor belt and injecting the roll with plastic net. As our farm enjoyed more efficient yields with every adjustment of his original design, Gary decided to help other farmers, too!

On the Road Again… and Again… and Again

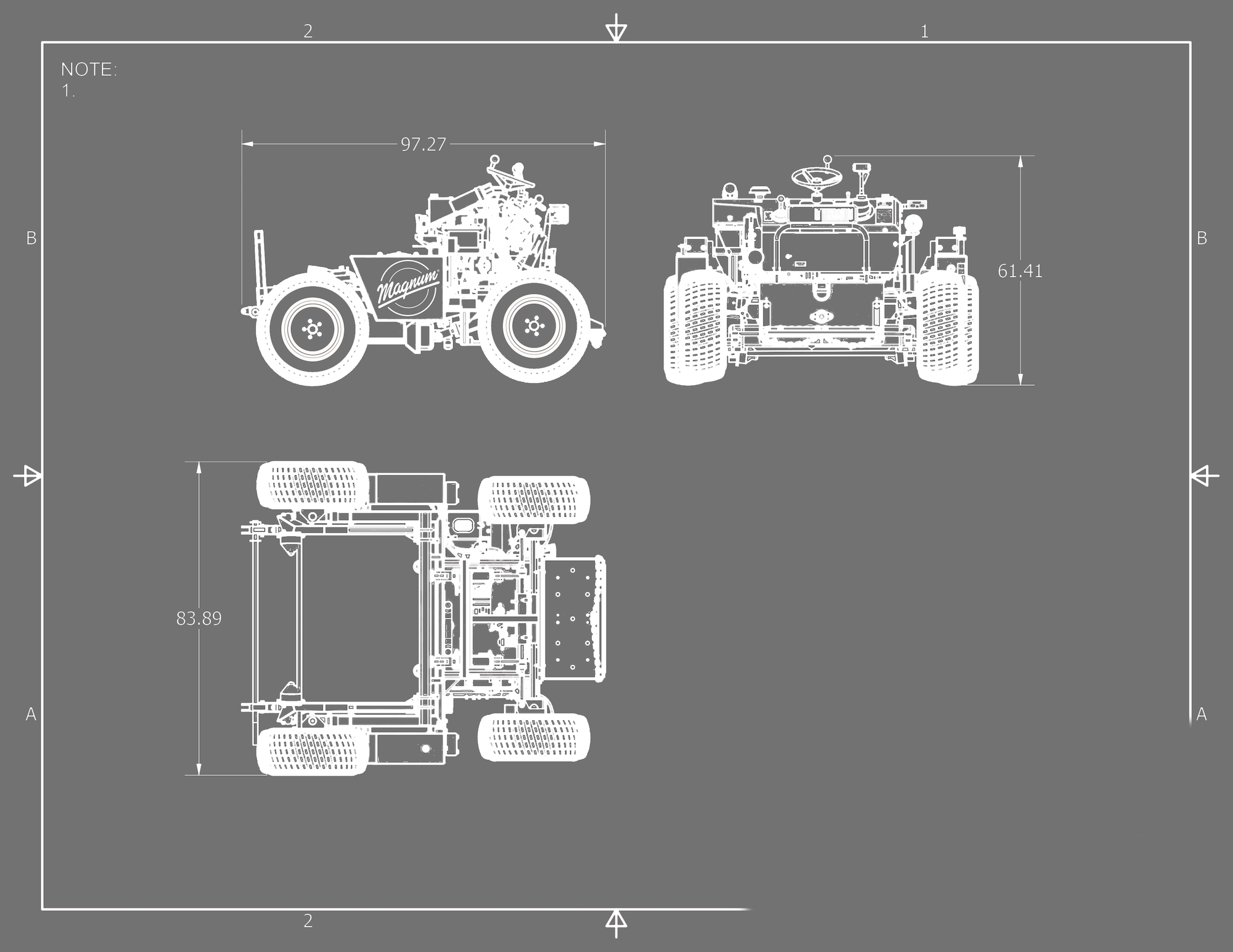

Gary and his son, Steven, spent the earliest days of Magnum working just as much to demonstrate his machine on other farms as he did on his own! While balancing a successful farm, young family, and budding business, he acquired enough backing to work on his first machine full-time. In a short amount of time, Magnum’s first shop came together and made history in the turf grass farming industry by officially creating the first big roll harvester, or BR for short, that would work in any soil condition and would keep the sod held together! This machine, and Steven and Gary’s commitment to prove its advantages, changed the reputation of the big roll, for good!

Designing the Ideal Turf Grass Farming Equipment

Since Gary didn’t want to leave his heritage behind him, he decided to use our family farm as a testing ground for further innovations as Magnum continued to make its mark on the industry. Through years of research and development, the BR became one of the most widely used big roll harvesters in the world.

But “good enough” has never been a part of our family values! To improve on this design even more, Gary and his son, Steven, worked together to develop our first innovation since the BR.

The SR

We streamline the sod harvesting process like never before by taking the widely loved BR harvester, and making it even more efficient. The patented anti-vibration cutting heads, a self-starting conveyor that eliminates hand wrapping net around the tube, a tube injector for easy tube addition for new rolls are just a few of the impressive upgrades on the SR harvester.. As one operator drives the tractor, another can control the tube injector, cutter settings, and other essential functions from the harvester itself.

This tag-team action revolutionized the turf grass farming industry when the SR made its debut. But yet again, our family’s core values of innovation, quality, and service rolled into yet another groundbreaking harvester.

The SRA

When Gary started sod farming, it would take teams of workers and hours of painstaking labor to harvest a complete crop. Through decades of dedication to innovation, his experience, as well as hours of working with our loyal and expert customers, led our family business to create the ultimate automatic sod harvester.

The SRA takes the streamlined design of the SR, and adds real-time telemetry, push-button controls, and dozens of other automation components. This turns what once took a team of laborers hours into an afternoon of work for just 1 person!

An Automatic Success

With the SRA, farmers can control every part of the sod harvesting process from the comfort of their tractor cab. The cost savings of one less laborer, paired with the efficiency boost attributed to automation, places this harvester among our most cost-effective options for small to large-sized operations, and everywhere in between. Read more about our automatic sod harvester options with this related read!

Automate Success With an Automatic Sod harvester

Of course, as your acreage increases, so will your need for new machines, netting, and parts! As our founders found out, there are many more avenues in need of innovation in the turf grass farming industry.

Netting a Loyal Following

While working to become the industry leader in big roll harvesters, we noticed that our customers needed netting that was just as unique as their operations. With this in mind, our team scoured the globe to find the highest-quality netting and the widest variety of options available. We also streamlined the installation process of field netting with machines designed with efficiency in mind!

Field Net Installers

Magnum’s field net installation equipment is unlike any other in our industry, and we like it that way!

The BN-1720 field net installer combines an automatic staking component with a roller designed to effortlessly unroll thousands of square feet of field netting. As the netting comes off the roll, a coulter pushes the net into the divot it makes in the soil. The net is then bunched together and tightly staked into the ground at a preset distance.

This implementation provides a multi-action operation that eliminates hours of work every planting season! It can also be adjusted for all the netting varieties we offer.

The BN-1720 was our first foray into innovating for this aspect of turf grass farming. However, our family values proved, yet again, that the best can always be made better!

Our SAS 300 field net staker takes hours out of the staking process by automatically driving dozens of specially designed stakes into the ground at a preset distance while a tractor, 4-wheeler, or golf cart-alike, pulls it along the field.

Innovative Netting Materials

Plastic big roll netting has long been the industry standard for large spans of crops due to its affordability and durability. Magnum supplies 3 strengths in standard widths of netting from 23” all the way to 46”. We also offer made-to-order options ranging from 30” to 48”. Plastic netting is fantastic for most all farms, but for the customers with specific jobs that demand strict requirements, Magnum meets every need!

Field netting provides a strong scaffolding that allows farmers to harvest even the most tender of crops. Magnum’s field netting options feature the strongest tensile strength and longest linear foot length of any field net like it. This means less reloading time and easier installation for every square foot!

BioHarvestNet big roll netting is the latest environmentally friendly netting solution taking the turf grass farming industry by storm! This innovative blend of 100% degradable fibers can span up to 3000 linear feet and comes in 30”, 42”, and 48” widths. While the linear feet is much shorter than plastic netting, the true benefits of BioHarvestNet go beyond the farmer’s field!

Most customers who look for BioHarvestNet’s biodegradable properties need efficient, effective installations that eliminate the need to remove the underlying netting. Since these rolls are made of jute and other natural fibers, they naturally degrade into the soil as the grass takes root. This saves on installation time and extra dollars in the long run!

Whether it’s a simple advancement like field netting or a complex innovation like our latest harvester, Magnum is building a brighter future for turf grass farming worldwide.

The Next Generation of Turf Grass Farming

As new generations of the Dover family take the helm of our company, we notice that many farms are experiencing similar transformations. To continue a decades-long tradition of serving our beloved industry, Magnum is pushing the boundaries of what’s possible from turf grass farming once more!

The SP Harvester

The next generation of sod farming deserves a next-generation harvester to meet the demands of our growing industry. By partnering with some of the biggest names in international agriculture, we’re proud to provide a self-propelled option (SP) to a new crop of turf grass producers!

The SP harvester features a John Deere Worldwide cab that gives one operator a comfortable front-row seat for every square foot of sod they harvest. This cab is positioned above twin anti-vibration cutters to help the expert eye of a farmer make quick adjustments as needed for high-quality yields. With a push-button panel and levers that control every aspect of the process, the SP offers a harvesting experience like no other.

For the fastest, most efficient harvest season yet, customers around the world are customizing their SP with our sales team to maximize ROI. Take a look at a few key considerations your farm should keep in mind before upgrading to our SP.

Upgrading to a Self Propelled Sod Roller

From Our Family Farm to Yours

Since Gary’s earliest days on the farm to the latest generation of innovations, our family continues a proud tradition of serving the turf grass farming industry with quality and courtesy. Whether you’re ready for a new machine, keeping an old one running, or improving any other aspect of your operation, trust the family that’s been in the industry for over a century!

Get no-hassle pricing online, or get in touch with our team to discuss your farm’s needs.